PCB용

에칭기/현상기 : 주문형 현상, 에칭, 세정기를 자유롭게 구성하여 공급합니다.

사용자의 사양에 따라 1대에 에칭기에서 PCB 에칭을 두

개조로 할 수 있고, PCB를 현상과 에칭을 동시에도 가능합니다.

물론 에칭과 에칭된 PCB를 수세를 동시에 작업 할 수 있습니다.

Base unit is available as an Base unit is available as an

optional extra (see below) |

| PCB 현상기/에칭기/박리기/Etcher /

Developer (ED-1020) (납기 2~4주) |

| A Spray Processor with many advanced features making an ideal upgrade to

a Bubble Etch Tank.

PCB

에칭 및 현상 기능을 동시에 갖춰 공급합니다. 또는 에칭-세정, 박리-세정,

현상-에칭..

- Digital temperature

control - Set & control temperatures accurately.

- Transparent case

design - Panels can be examined after processing without removing.

- Integral Spray Wash

Tank - Washes the entire board holder to keep whole etching process clean.

Fitted with adjustable spray bars.

- Etches PCB in less than

90 seconds! - 3-4 times faster than a Bubble Etch Tank.

- Developer or Etcher

- As well as etching the unit can be used to develop photoresists.

- Bottom drain with secure

fastening - No syphoning necessary.

- Splash hopper

included - Helps to contain chemistry to aid clean processing.

- Safety cut-out on

lid - Motor cuts off if lid is raised during etching.

- Optional Base Unit

available - Places the top of the processing tank at an efficient working

height of 110cm

- New Board Holder -

Takes multiple small boards. Low profile design means less etchant or developer

collects on board holder keeping processing cleaner.

- Digital timer controls

processing time - As the board is not immersed in liquid, there is no

over-processing after completion. This makes over-etching very difficult.

- 10" x 12" (254 x 305 mm)

Board capacity

- Dimensions :H 650, W

440, D 360 mm

- Optional Base Unit

Height : 450mm

|

상기 제품의 외형은 당사에

의해 예고 없이 변형이 됩니다.

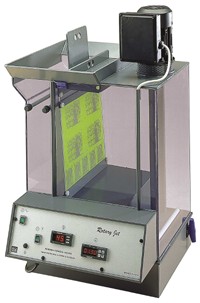

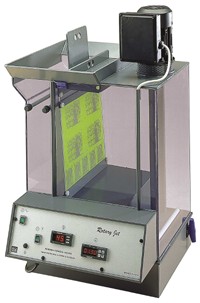

Etching

Machine

a low cost rotary etching machine ideally suited

to the manufacture of prototype and small batch quantities of PCBs. As well as

etching the unit can also be used for spray developing and spray resist

stripping. The machine is of a sturdy PVC construction and is mounted on a stand

which places the machine at a convenient working height. Etching solution is

contained in a tank at the base of the machine. It is heated by a powerful

quartz heater which assures a short warm up time and constant temperature which

is controlled electronically. Boards up to 300 x 500mm can be etched although

several smaller boards can be placed in the special board carrier, the handle of

which protrudes out of the machine eliminating operator contact with the

etchant. The machine etches one side at a time and so for double sided PCBs the

board holder is rotated 180º before the second etching cycle. In front of the

etching chamber is a built in overflow wash tank for the rinsing of the etched

boards. The triangular form of the body of the machine makes it ideal to place

in a corner of a room. The efficiency of this spray etcher has been proven by

line resolution of better than 0.1mm and etching speed of only 90 seconds with

fresh ferric chloride.

a low cost rotary etching machine ideally suited

to the manufacture of prototype and small batch quantities of PCBs. As well as

etching the unit can also be used for spray developing and spray resist

stripping. The machine is of a sturdy PVC construction and is mounted on a stand

which places the machine at a convenient working height. Etching solution is

contained in a tank at the base of the machine. It is heated by a powerful

quartz heater which assures a short warm up time and constant temperature which

is controlled electronically. Boards up to 300 x 500mm can be etched although

several smaller boards can be placed in the special board carrier, the handle of

which protrudes out of the machine eliminating operator contact with the

etchant. The machine etches one side at a time and so for double sided PCBs the

board holder is rotated 180º before the second etching cycle. In front of the

etching chamber is a built in overflow wash tank for the rinsing of the etched

boards. The triangular form of the body of the machine makes it ideal to place

in a corner of a room. The efficiency of this spray etcher has been proven by

line resolution of better than 0.1mm and etching speed of only 90 seconds with

fresh ferric chloride.

| Specifications |

| Maximum Panel Size: |

300 x 500mm |

| Sump Capacity: |

30 litres |

| Dimensions: |

Width 650 x Depth 690mm |

| Electrics: |

220-240V/50Hz 1ph. |

| PCB 현상기, 박리기,

세정기 (Two-Tank PCB Processing Unit - Develop, Strip or Tin and Wash)

|

|

|

|

A cost effective improvement over the standard Universal Tank. This unit

includes a thermostatically controlled heater to cover PCB chemical temperature

range of 10 to 55도. The tank can be thus selected for Develop (25도), Resist

Strip (45도) or Immerse Tin (21도).

The integral spray wash tank offers safer, cleaner and more efficient

processing of boards than the standard Universal Tank and, being wider, also

gives greater stability. The spray wash tank is solenoid operated with all

electrical controls located on the front panel. Connections are provided at the

rear for drain and cold water requirements.

Complete with an IEC socket and supplied with 2 metres mains cable with

moulded 13 amp plug and a syphon.

- Injection moulded as one piece - no risk of leaks from welded

seams.

| Width: |

275mm. |

| Depth: |

525mm. |

| Height: |

380mm. | |

반도체 - PCB - LCD - FPC

연구장비-생산장비, 실습-연구기자재, 전자재료 공급

TEL :

02-868-0661 (代)

pcb21@korea.com