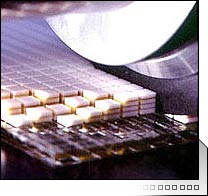

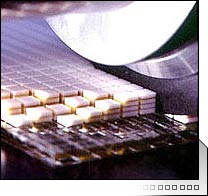

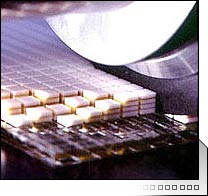

Silicon

Wafer dicing SAW

Quality Manufacturer of High Precision Diamond

Dicing Blades and Dicing Saws Committed to Customer Service

Excellence

Since 1978, Thermocarbon has closely worked

with its customers to solve a wide variety of dicing application problems

ranging from providing the user with the optimum cutting parameters for all

types of difficult materials, to recommending proper mounting and handling

procedures.

Our professional sales staff are constantly continuing their

training within the dicing application processes so that they may better assist

our customers striving to increase yield and productivity. If Thermocarbon does

not have an immediate answer, we will offer you complete R&D services in our

dicing lab to work toward a solution. There is never a charge for this service

to you, the customer. |

|

|

Blademaster® and Dicemaster® Diamond Dicing

Blades

Our product line includes the distinctive Blademaster® and Dicemaster® diamond dicing blades, which are

used and favored throughout the world in wafer dicing applications because of

their precision tolerances, self-sharpening characteristics, and consistent

reliability.

The Dicemaster® resin-bonded universal wafer dicing blade represents

state-of-the-art precision in ultra thin diamond grinding wheels. It is

designed to:

- chip less

- run cooler

- last longer

- cut with closer tolerances than any other blade on the market

Des. 381,668 & 387,364

|

Tcar® 864-1 Unparalleled

Flexibility |

|

|

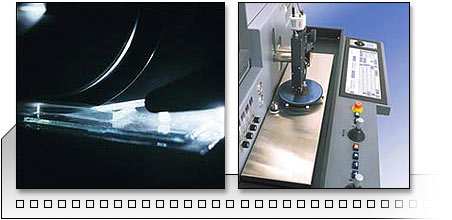

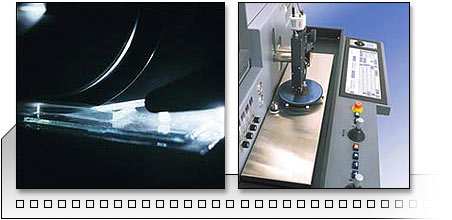

.050" Thick Silicon

Cut in symmetry

to center artwork utilizing the patented "Wafer Zero" of the Tcar 864-1 Programmable Dicing Saw

manufactured by Thermocarbon Inc.

Overall cut diameter:

3.54"

Process Time: 16

Minutes | |

Tcar® 864-1 Wafer Dicing Saw

The Tcar® 864-1 programmable dicing saw marks a new era in wafer dicing

technology. Designed and manufactured in the United States by the industry

leader in diamond grinding wheels, the Tcar® 864-1 offers:

- exceptional power

- accuracy

- infinite programming flexibility

- made in the USA

Our supportive product line includes:

- blades

- flanges

- spacers

- dresser plates

- lapping systems

|

| Call today for your free Thermocarbon Product and

Diamond Grinding Technology Millennium Handbook. (Updated 11/01/01) Valuable

source book for the "How To" of selecting dicing equipment and blades, actual "Case Histories" covering difficult dicing

applications, as well as everything you need for ordering diamond dicing blades, flanges, adapters, and equipment.

| |

Wafer Dicing Excellence

Whether

wafer dicing thin silicon materials or cutting into heavy cross sections of hard

brittle materials, such as ceramic and sapphire. Thermocarbon's wafer dicing saw

and diamond grinding wheels provide dicing and diamond grinding

excellence for all types of materials and applications including:

Thermocarbon backs all of its products with a complete customer support

program designed to assure the maximum return on your investment. This support

includes 24-hour open communications, free consultation, custom design services,

sample blades, and free R&D services.

Contact us for more

information about our diamond dicing

blades, wafer dicing saws, and accessories.

TEL :

02-868-0661 (ÓÛ) FAX :

02-868-0664

Tcar® 864-1 Wafer Dicing Saw

A Complete Turnkey System

· Tcar® 864-1 Complete Solution · Tcar® 864-1 Features

· Tcar® 864-1

Technical Specifications · Tcar® 864-1 Dicing Laws

|

Controls

Literally at your fingertips, the Tcar® 864-1 wafer dicing saw takes into account

the ergonomics required for efficient operation. Controls include keyboard, push

buttons, joysticks, and track ball. The full-color dual monitors provide

complete separation of text and video, which permits all-critical parameters to

be viewed at a glance. All this combined with critical control redundancy at the

monitor screen and on-line, real-time graphics display provides the Tcar® 864-1

wafer dicing saw with unsurpassed operational flexibility.

|

Power and logic lockable

pullout drawers facilitate easy and safe maintenance. Electronic compartments

are physically isolated from all oil and water flow components via a drip pan

that runs corner-to-corner between the lower and upper sections of the

cabinet. |

Smaller footprint

The Tcar® 864-1 cabinet design meets the need for

reduced space requirements on the manufacturing floor without giving up

accessibility for ease of maintenance. In fact, because no side access is

required for maintenance, multiple units may be installed side by side, thus

using as little as two-thirds the floor space of competitive units! And the

removable control panel allows the Tcar® 864-1 wafer dicing saw to pass through

a standard office door. Units are leveled in place using four leveling feet,

which are all accessible from the front of the saw.

|

Infinite chuck rotation¹

and programming steps in addition to a four-inch "Z" travel allows for any

dicing geometry. Patent-pending chuck brake system ensures solid locking of

positions for high accuracy. |

| Possessing an excellent tactile feel, the rugged keyboard,

sealed to NEMA 4, will stand up to the harshest of dicing environments.

|

|

|

Optics, spindle, blade, and

wash bar coolant flow, as well as vacuum and air pressure, visible at a glance.

|

Tcar® 864-1 Wafer Dicing Saw

Standard Features

· Tcar® 864-1 Complete Solution · Tcar® 864-1 Features

· Tcar® 864-1

Technical Specifications · Tcar® 864-1 Dicing Laws

|

"Standard" Features means just that - no additional costs! Where options are

given, simply choose which system best suits your needs for installation on your

Tcar® 864-1 wafer dicing saw.

- Cast iron axis construction mounted on solid Granite Block for

rigidity and stability.

- Unique X, Y, Z, and Theta Double Closed Loop control.

- Unlimited Theta rotation and large four-inch "Z"

travel.

- Powerful three horsepower variable-speed spindle.

- Two full color high-resolution monitors.

- Real time graphics display.

- Powerful integrated PC-based program introduces patents-pending

features such as:

o Flange Clearance Stop® ¹ - a patented program that prevents

the collision of the blade adapter's periphery with the top surface of the

workpiece during the dicing operation.

o Wafer Zero® ² - Patent

pending Wafer Zero® automatically transfers the home position from the chuck to

the wafer center where it is needed, eliminating a very time-consuming and

difficult process.

o Align Offset® ³ - Patent pending "Align

Offset®" (Align here/cut there) allows alignments to be made on any portion of

the wafer's artwork without having to actually make a cut there. The first cut

is made a specified distance from the alignment location.

|

|

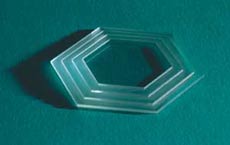

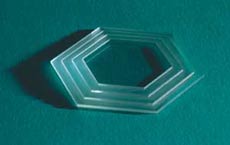

The Tcar® 864-1's

pop-up SmartGrafix® window simplifies creating complex shapes such as the

circular optical filter shown above.

The round optical filter above was diced from a rectangular glass

substrate using the diverse flexibility of the Tcar® 864-1.

|

- Your choice of Point-and-Click High Speed or Split-Field Optic

alignment systems.

- True Illumination system allows high contrast for easy viewing of

gold on white or solid white ceramic substrates.

- Adjustable electronic dual cross-hair targeting

system.

- Off-chuck automatic height sensing by the cut or wafer.

- Direct measurement capability in X, Y, and Theta.

- Programmable entry feed rate and overcut length control the blade as

it enters the wafer and ramps up to the final feed rate.

- Five sensors to protect your investment: spindle air, coolant,

temperature, blade coolant, and chuck vacuum.

- Conductive or non-conductive dicing blades.

- Front panel, coolant trough, and chuck pan, made of stainless

steel and powder-coated to withstand years of continuous operation.

The Tcar® 864-1 wafer dicing saw

offers exceptional power, accuracy, and infinite programming flexibility in a complete turnkey solution. In addition, it

adheres to the three basic laws of wafer dicing hard

and brittle material.

|

|

This intricate glass geometric shape,

with its .065" stair width, requires a multiplicity of rotation, depth, and

step-over commands. Using a single .015" thick Dicemaster® blade for the entire

operation, the Tcar® 864-1 was programmed and the start button

pressed.

|

Tcar 864-1 Technical Specifications

· Tcar® 864-1 Complete Solution · Tcar® 864-1 Features

· Tcar® 864-1

Technical Specifications · Tcar® 864-1 Dicing Laws

|

Accuracy: The maximum difference

allowed between the position of the servo and the position of the spindle nose,

externally measured over full travel with a laser interferometer at 24°

C.

Repeatability: Specified over full travel, as the standard

deviation, calculated from differences recorded for 10 identical displacements

to the same position.

| Cutting Axis

¡°X¡± |

| Closed loop positioning system |

Brushless DC servo |

| Drive system |

2 mm/rev lead screw with

anti-backlash |

| Maximum travel |

295 mm |

11.6 inches |

| Minimum speed |

0.050 mm/sec |

0.002 in/sec |

| Maximum speed |

130 mm/sec |

5.1 in/sec |

| Resolution |

0.25 micron |

0.00001

inch |

| Index Axis

¡°Y¡± |

| Closed loop positioning system |

Brushless DC servo with linear

optical encoder |

| Drive system |

1 mm/rev lead screw with

anti-backlash |

| Maximum travel |

157 mm |

6.2 inches |

| Resolution, linear encoder |

0.50 micron |

0.00002 inch |

| Repeatability |

1.5 micron |

0.00006 inch |

| Accuracy |

3 micron |

0.00012

inch |

| Vertical Axis

¡°Z¡± |

| Closed loop positioning system |

Brushless DC servo with linear

optical encoder |

| Drive system |

1 mm/rev ball screw with

anti-backlash |

| Maximum travel |

95 mm |

3.7 inches |

| Resolution, linear encoder |

0.50 micron |

0.00002 inch |

| Repeatability |

1.5 micron |

0.00006 inch |

| Accuracy |

3 micron |

0.00012 inch |

| Height sense repeatability |

1.5 micron |

0.00006

inch |

| Rotary Axis

¡°Theta¡± |

| Closed loop positioning system |

Brushless DC servo with high

resolution internal rotary optical encoder |

| Drive system |

100:1 anti-backlash worm

drive |

| Chuck brake |

Air lock system |

| Rotation (infinite) |

360 degrees |

| Resolution, rotary encoder |

.0010 degrees |

3.6

arc-seconds |

| Chuck |

| Cross hatched (vacuum) |

152.4 mm |

6 inch |

| Porous stone (vacuum) |

152.4 mm |

6 inch |

| Other standard configurations

available |

| Spindle |

| Minimum blade diameter |

48.2 mm |

1.9 inch |

| Maximum blade diameter |

76.2 mm |

3.0 inch |

| Type |

Titanium housing, air bearing, water

cooled, infinite variable speed |

| Minimum speed |

1,000 rpm |

| Maximum speed |

30,000 rpm |

| Maximum power output |

2,250 watts |

3

horsepower |

| Optics |

| Dual high resolution color monitors |

355.6 mm |

14 inch |

| Camera |

CCD, S-Video |

| Typical magnification |

150x |

| Targeting system |

Split-field, electronic cross

hair |

| Typical resolution |

3 microns/line |

.00012

inch/line |

| Utilities |

| Electrical |

208 VAC-240VAC single phase,

20A |

| Air (spindle) |

80 psi, dewpoint 45 degrees @ 100

psi |

| Water |

40 psi to 100 psi |

| Vacuum |

24 in. Hg,

continuous |

| Dimensions |

| Height |

163 cm |

64 inches |

| Width |

119 cm |

47 inches |

| Depth |

105 cm |

41 inches |

| Weight |

602 Kg |

1325

lbs |

Note: All specifications subject

to modification without notice

How the Tcar® 864-1 Wafer Dicing Saw Adheres to

The Three

Basic Laws for Wafer Dicing

Hard and Brittle Materials

· Tcar® 864-1 Complete Solution · Tcar® 864-1 Features

· Tcar® 864-1

Technical Specifications · Tcar® 864-1 Dicing Laws

|

To be successful in dicing hard and brittle

materials, the fundamental requirements of rigidity, power, and cooling must be

considered for each system component selection. You also need to understand that

each component of the sawing process cannot create sawing efficiency alone. Each

component that makes up your interactive system must be compatible. If just one

component is wrong, it could render all other properly selected components

ineffective.

RigiditySystem rigidity

plays a major role in sawing efficiency and quality, whether dicing thin silicon

materials at inch-per-second feed rates, or cutting into heavy cross sections of

ceramic-based materials. |

|

|

A rigidly mounted spindle with virtually no end play or vibration is

mandatory for dicing and diamond grinding. Additionally, to maintain the

perpendicularity of the spindle to the X slide is essential for the diamond

blade to run true throughout subsequent operations.

The Tcar® 864-1 wafer dicing saw is

exceptionally solid in its foundation. X, Y, Z, and Theta are constructed of

stable cast iron, mounted on a solid granite base and cradled into an all-steel

independent frame cabinet.

Utilizing the latest technology in high precision and frictionless linear

guide ways, each axis is driven using powerful DC Servo motors to ensure smooth

and accurate motion in every direction.

All this, combined with Heidenhain optical encoders and the most

sophisticated closed-loop feedback circuit ever designed, takes precision wafer

dicing to a whole new level.

Power

Packing the most powerful

air bearing spindle for its size, the Tcar®

864-1 wafer dicing saw delivers a full three horsepower at 30,000 RPM. The

spindle is completely enclosed in a corrosion-resistant titanium housing and has

an invar shaft to reduce the coefficient of thermal expansion for improved

stability at the cutting edge.

The frequency inverter, utilizing 100% digital architecture, provides for

variable speeds ranging from 1,000 to 30,000 RPM and maintains constant torque

during acceleration. The circuit's extremely fast response time eliminates

damaging power loss during the actual cutting process when dicing your most

demanding applications.

Cooling

Effective cooling of

the diamond blade at the point of contact with the material being processed is

essential for any diamond cutting and grinding application. Yet, cooling is one

of the more overlooked conditions in the system.

Dual nozzles provide two separate streams of coolant to the cutting

interface, and at an angle to the cutting edge of the blade, so that each stream

will favor one side of the diamond blade after providing the necessary coolant

to the leading edge. This approach provides the necessary coolant to all of the

critical areas of the cutting blade, with no loss of the directional flow

required for removing the debris generated during cutting.

The Tcar® 864-1 diamond blade housing incorporates efficient dual-nozzle

cooling jets that are easily adjustable in every direction to accommodate all

dicing applications, no matter how thick the material is to be processed.

Front-mounted flow meters facilitate easy adjustment and consistency of coolant

velocities.

The Tcar® 864-1 wafer dicing saw offers

exceptional power, accuracy, and infinite programming flexibility in a complete turnkey solution.

Flanges and Spacers

While most end users will take considerable steps in

assuring the rigidity of the machine they purchase, they may overlook the

critical mounting requirements, such as the flanges and spacers,

necessary for the diamond blade. No matter how well the diamond blade was

manufactured to run true, it can only run as accurately as the surfaces it comes

into contact with. The bearing surfaces of the flanges or spacers

must be flat, clean, and parallel.

|

|

|

Thermocarbon offers a wide range

of standard blade flanges and spacers to fit all dicing saws and

conventional sawing equipment. Our flanges and spacers conform to

exacting specifications to ensure that you get the highest performance from your

diamond blades.

Our Flanges and Spacers Are Designed for Longer Blade Life

The most frequent cause of blade breakage and oversize cut widths with

relation to blade thickness is improper flange torque or poor flange

quality. Thermocarbon's precision dicing blade flanges and

spacers are constructed of the highest quality stainless steel and

are also available in other materials upon request. They are machined in our own

modern tool manufacturing facility to exact specifications that ensure

parallelism, proper blade exposure, balance, and precise bearing surfaces. Our

demanding specifications ensure:

|

- even cut quality

- minimal edge chipping and kerf

- high dicing blade life and free cutting

performance.

|

Maintenance and Repair for all Flanges and Spacers

Thermocarbon provides maintenance and repair for all

dicing blade flanges and spacers in order to support your efforts

in achieving consistent high quality standards for your wafer cutting and dicing

operations.

Metal Dicing Blade Spacer

Thermocarbon also offers as a stock item the MBS-063 Metal Dicing

Blade Spacer for use on desktop dicing saws using both the resinoid and metal

bonded type dicing blades. The MBS-063 eliminates the need to readjust dicing

blade coolant nozzles and scope positions when alternating between the two types

of dicing blades.

Quality Diamond Dicing Blades for Dicing and

Precision

Cutting

Thermocarbon's widely used Dicemaster® and Blademaster®

diamond dicing blades have been consistently favored worldwide for their:

- precision tolerances

- self-sharpening characteristics

- consistent reliability.

Resin-bonded Diamond Dicing BladesDicemaster® resin-bonded universal diamond dicing blades

are state-of-the-art in diamond grinding technology. Dicemaster diamond blades

are designed to:

- chip less

- run cooler

- last longer

- cut with closer tolerances than any other dicing blade on the market.

|

|

|

Highest Quality Abrasives

Dicemaster® and Blademaster®

diamond dicing blades are composed of the highest quality diamond abrasives.

These diamonds are evenly dispersed to ensure the highest quality cuts from

start to finish, even in the most difficult materials. An almost infinite

variety of diamond/filler combinations are available to create the wide range of

performance capabilities necessary to accommodate your various application

requirements.

Self-Sharpening

Your technicians will appreciate Dicemaster's

remarkable self-sharpening characteristics, which eliminate the need for

dressing procedures and costly interruptions to production.

High Yields

Thermocarbon's unequaled production and quality control

standards ensure that you will receive consistent performance from diamond blade

to diamond blade. The result is higher yields, faster feed rates, and increased

productivity.

Personalized Service

|

In order to specifically address your

individual needs, our experienced staff will help you to choose from among our

various cut-off saw diamond dicing blades. Dicemaster® and

Blademaster® high-quality diamond blades are available in a complete range of diameters from 2" through

4.6" to fit all dicing saws and conventional grinders. Thicknesses are available

from .0015" through .2500" with various tolerance levels starting at + .0001".

All blades are electrically conductive unless otherwise stated.

|

Specialty Configurations

In addition to a complete line of standard

diamond blades, Thermocarbon offers specialty configurations, diameters, and

thicknesses to meet your most demanding requirements. Our Research &

Development lab, which is one of the most sophisticated in the country, will

custom formulate the dicing blade matrix to best meet your most demanding

requirements.

Quality Diamond Dicing Blades for Dicing and

Precision

Cutting

Thermocarbon's widely used Dicemaster® and Blademaster®

diamond dicing blades have been consistently favored worldwide for their:

- precision tolerances

- self-sharpening characteristics

- consistent reliability.

Resin-bonded Diamond Dicing BladesDicemaster® resin-bonded universal diamond dicing blades

are state-of-the-art in diamond grinding technology. Dicemaster diamond blades

are designed to:

- chip less

- run cooler

- last longer

- cut with closer tolerances than any other dicing blade on the market.

|

|

|

Highest Quality Abrasives

Dicemaster® and Blademaster®

diamond dicing blades are composed of the highest quality diamond abrasives.

These diamonds are evenly dispersed to ensure the highest quality cuts from

start to finish, even in the most difficult materials. An almost infinite

variety of diamond/filler combinations are available to create the wide range of

performance capabilities necessary to accommodate your various application

requirements.

Self-Sharpening

Your technicians will appreciate Dicemaster's

remarkable self-sharpening characteristics, which eliminate the need for

dressing procedures and costly interruptions to production.

High Yields

Thermocarbon's unequaled production and quality control

standards ensure that you will receive consistent performance from diamond blade

to diamond blade. The result is higher yields, faster feed rates, and increased

productivity.

Personalized Service

|

In order to specifically address your

individual needs, our experienced staff will help you to choose from among our

various cut-off saw diamond dicing blades. Dicemaster® and

Blademaster® high-quality diamond blades are available in a complete range of diameters from 2" through

4.6" to fit all dicing saws and conventional grinders. Thicknesses are available

from .0015" through .2500" with various tolerance levels starting at + .0001".

All blades are electrically conductive unless otherwise stated.

|

Specialty Configurations

In addition to a complete line of standard

diamond blades, Thermocarbon offers specialty configurations, diameters, and

thicknesses to meet your most demanding requirements. Our Research &

Development lab, which is one of the most sophisticated in the country, will

custom formulate the dicing blade matrix to best meet your most demanding

requirements.

Thermocarbon Ordering Information for

Diamond Dicing

Blades

Please use the following configuration sheets to

determine the correct diamond dicing blades for your dicing application.

Thermocarbon's service engineers are also available to assist you in the

selection of the blade best suited for your application.

Diamond Dicing Blades

2" O.D. x 1"

I.D.

2.050", 2.187",

& 2.25" Diameter Series

3"

O.D. x 1.575" I.D.

3" O.D. x 2"

I.D.

4.6" O.D. x 3.5" I.D.

4", 4.3", & 4.5"

Diameter Series

Resin-Bonded Diamond Dicing Blade

Matrices |

»ó±â

Á¦Ç°¿Ü¿¡ ´ç»ç´Â ¸¶½ºÅ© ¾ó¶óÀÌ³Ê ¹× ½ºÇÉÄÚÅÍ, ½ºÇÉ¿¡ÃÄµî ´Ù¾çÇÑ ¹ÝµµÃ¼ ¿¬±¸Àåºñ¸¦

Á¦Á¶, ¼öÃâÀÔÀ» ÇÕ´Ï´Ù. ¸¹Àº ¹®ÀÇ ±â¿ûÇÕ´Ï´Ù.

TEL :

02-868-0661 (ÓÛ) FAX :

02-868-0664