![]() 스핀코터(SPIN COATER) 사양 첨부파일 클릭하시면 자세하게 보실수 있습니다.

스핀코터(SPIN COATER) 사양 첨부파일 클릭하시면 자세하게 보실수 있습니다.

동아무역은 스핀코터 (Spin coater), 디벨러퍼, 스트리퍼 등 최 첨단 신 기술개발 및 제조를 통해 차 새대를 생각하는 기업 입니다.

또한 스핀코터 단일 아이템으로 수출유망중소기업으로 중소기업청에서 인증을 받았습니다. 동아무역은 20년 노하우와 기술과 믿음으로 항상 함께 하겠습니다.

스핀코터와 관련하여 한국저작권위원회에 2건, 특허청에 1건의 특허와 1건의 실용신안 등록을 보유하고 있습니다.

당사가 제조하는 초 정밀 그래픽 스핀코터는 세계 최초로 특허를 받고 국내 기업체 , 이공대 연구실, 국가 연구소 및 전 세계에서 절찬리에 사용 하고 있습니다.

스핀코터 납품 실적 (국내 기업체 연구소, 대학교, 이공대 대학원, 국가 연구소 공급 ! 조달청 등록)

L

G그룹 계열사, 삼성그룹 계열사, 카이스트, 성균관대, 삼성LED, 경북대, 서울대, 연세대, 서강대, 한국화학연구원, 고려대, 나노소자 특화팹 센터(정부기관), 서강대,

한양대, 삼성전기, 융합과학기술대학원, 삼성모바일디스플레이,삼성테크원, 삼성전자DMC연구소, LG전자기술원, LG필립스LCD,GS칼텍스, 삼성코닝절밀, 제일모직,경북대,

전북대, LG화학연구원, 포항공대(포스텍),전남대, 한국기계연구원, 대양전기공업, 국민대, 세종대, 잉크테크, 한국원자력연구원, SI CNF, 이노칩텍크널러지,

동진쎄미켐, 한국과학영재고,광주과학기술원(Gist), 경기과학고, 삼성 종합기술원,삼성전자, 울산대, SK연구소, LG전자기술원, 휴브글로빌, 미주과학, 선문대, KBT,

한남대, 한국전자통신연구원(ETRI), 한국생산기술연구원, 대구경북과학기술연구원, 새한토레이, 포항지능로봇연구소, 제일모직, 세종대, 동국대, 기초지원과학기술연구원,

엔씨케이, 쌍용머티리얼, 노루코일코팅, 홍익대,EEWS(카이스트내),부산대, 건국대, 경성대, 충남대, 동명이화학, 쎄로닉스, 조선대, 울산대, 이화여자대학교,

코멕, 힘스, 카토릭대, 태인, 창성,LG전자, 창원대, 한국과학기술연구원(KIST), 삼양옵틱스, PNC트레이딩, 삼전순약, 경성대, 단석산업, 대덕과학,

충북대, 엘케이랩코리아, 숭실대, 영남대, 석경 AT, 웅진케미칼, 인제대, , 알파하이테트, 공주대, LG실트론, 한국전기연구원,

QSI, 아이넥서스, 성호씨그마, 씨에스텍, 경성대, 나노종합팹센터(경기도), 뉴영엠테크, 비젼테크, 충남대, 유스텍, 국민대, 두산메카텍, KAIST(한국과학기술원),

강원대, 광운대, 켐백스, 경희대, 경원대, 대구대, 한국항공대학, 이건창호, 한멤스웨어, 동성과학, 한국기업정보연구원,

원광대, 자동차부품연구원, 세심광전자기술, 아주대, 철강대학원, 화인, 사이언스맥스, 나노팹쎈터(카이스트),

영남대, 한국잉크테크, AM테크놀로지, 부경대, 제주대, 안양대, 자동차부품연구원, 서울시립대, 삼성전기 중앙연구소, ,아프로 R&D, 그린바인더,호남대,

욱성화학, 광명이화학, 포사이언스, 경상대, 지엔에스, YMS 코리아, 에스엘텍, 알파하이텍, 도은, NCK,

나비바이오테크, VAT사인언스, 한텍, DS과학, 쓰리샤인,외 다수.

기타 업체 연구소 및 대학(연구실), 미국, 일본, EU(영국, 독일, 스위스, 프랑스 등등), 중국, 싱가폴, 인도, 파키스탄, 방글라데시, 이집트 등에 수출 (약 15개 국가).

이외 회사 기밀 보호를 원하는 거래처 (딜러 포함), 특수 공급된 업체는 업체의 사정에 의해서 제외시켰으며, 기타 및 이외 추가 공급된 업체

(연구소,대학원,연구실, re-sellers/30여곳)들이 있습니다. 상기 대학 연구실 및 기업체에 다수 또는 복수로 100여대 이상 공급 하고 있습니다.

20년 노하우! 이제 더 이상 외제를 사실 필요없이 당사가 제조하는 스핀코터로 사용하십시오. Quality Good, A/S는 3일이내!

초 정밀 디지탈 그래픽 스핀코터(세계최초 특허 취득. 허용 오차 ± 1 R.P.M 구현! 세계 TOP ! 명품 스핀코터 !

|

스핀코터 (ACE-200) /베스트셀러 |

|

|

글로브 박스형 스핀코터(ACE-200) |

TEL : 02 - 868 - 8787 (代)

초 정밀 스핀코터 시리즈

세계

최초 그래픽 스핀코터, 특허 인증 취득 :

Wafer, Glass, 각종 시료, 등등으로 스핀 코팅

데이터를 실시간 그래픽 및 문자모드로 자유롭게 구현 스핀코터

세계 어느 스핀코터에 비해 기능 및 성능이 우수 및 Best Price공급 ~Precision High Quality !! 납기 3일 이내

|

P style="MARGIN-TOP: 0px; MARGIN-BOTTOM: 0px; MARGIN-LEFT: 10px; LINE-HEIGHT: 120%"> ♂ Specification : 글로브 박스에 적용에도 최적.

세계적 베스트셀러 스핀코터 (성황리에 수출) |

초 정밀 중형 디지털 스핀코터 - 모델: TOP-8

♂ Specification

|

|

초 정밀 대형 디지털 스핀코터 - 모델: ACE-1200

♂ Specification

|

스핀코터에 대한 자료를 첨부했습니다. 클릭하시면 자세한 스핀코터에 대한 자료를 보실수 있습니다.

TEL : 02 - 868 - 8787 (代) pcb@naver.com

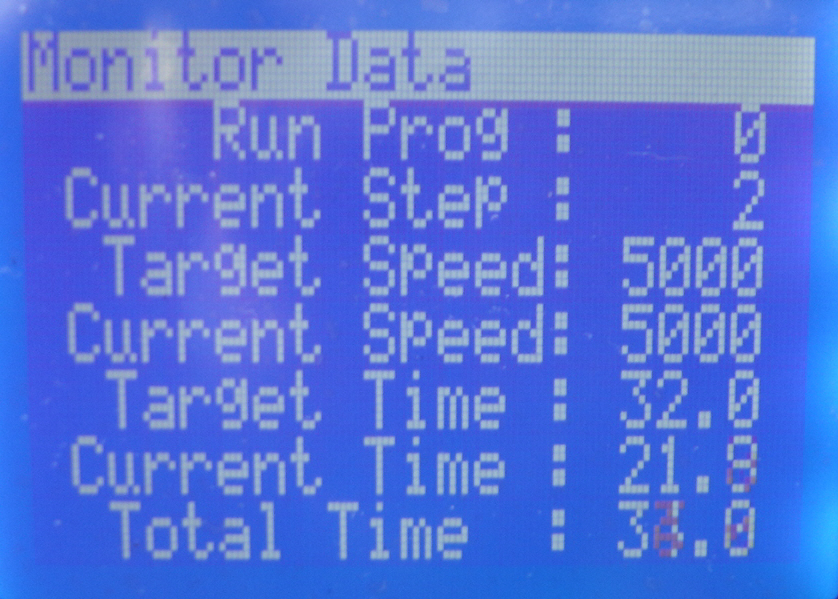

당사가 제조하는 스핀코터는 그래픽 화면 (LCD의 그래픽화 구현: 실시간으로 스탭별로 스핀 데이터를 그래픽 또는 문자모드로 자유롭게 볼 수 있음)

특징

1. 0

또는 50 ~ 8,000 R.P.M까지 스피드를 자유롭게 올리고

내리면서 사용할 수 있습니다. (Speed R.P.M : Up

& Down Free: 3,000 or 6,000/ Sec)

2. controller 보드 하나로 스핀코터를 구현하므로

고장이 거의없고, 만약 발생시 A/S가 아주 간단합니다. (A/S : 3일 이내 : 내부, 외부 장치 Compact화 구현)

3. 스핀코터의 외형 높이를

최대한 낮게 제조해서 글로브 박스안에 놓고도 용이하게 사용할 수 있습니다.(높이 200 mm:

글로브 박스에 적용에도

최적입니다.)

4.

100 스탭, 100 프로그램을 사용 하므로서 자유롭게 원하시는 스핀코터 데이터를 얻을 수 있습니다. (실시간 그래픽으로 스탭별로 코팅과정을 볼 수

있습니다. 세계최초 특허 획득)

5.

spin controller의 프로그램으로 스핀코터 동작시 초보자도 쉽게 사용할 수 있게 구현 했습니다. (디지탈 방식 스핀코터 채택)

6. 스핀코터의 볼 청소를 아주 쉽고, 간단하게 할 수 있습니다.

7. 외국 스핀코터와

비교할 때 다양한 기능 및 좋은 성능에 비해 스핀코터 가격을

저렴화 시켰습니다.

8.

스핀코터의

안전장치 : 버큠이 척과 시료에

안잡히면 작동이 안되어 운영자의 안전을 최우선으로 고려하여 개발, 생산했습니다.

9. 스핀코터 셋팅시킨 R.P.M 수치와 실제로

돌아가는 R.P.M을 볼 수 있어 회전 정밀도를 순간, 순간 확인할 수 있습니다. (고 정밀도 스핀코터 실현화)

10. 당사가 공급하는

스핀코터는 내부 구조가 spin motor + power supply + simple controller (board)로 구성되어 있어서 마치

PC를 업그레이드 하듯이

간단하게 수리가 가능하므로(2~3일 이내) 보다 안전하고 편리하게 사용 하실수

있습니다.

11. 스핀코터 전용의 강력한 모터와 프로그램을 연결하여 high R.P.M 구현시도 급 정지를 구현

함으로서 여러 가지 재료를 응용하여 귀사의 연구 개발에 큰 기여를 하는 스핀코터입니다.

또한 실시간 구현되는 회전의

동작을 그래픽으로 확인하므로서 코팅의 데이터를 쉽게 구할수 있습니다.

12. 위치제어 기능이 있어 정지시 시료(웨이퍼, 글라스 등등)를 원하는 위치에 정지 기능이 있어 시료 Handling에도 최적입니다.

13.

저속, 고속 R.P.M 에도

안정적으로 코팅 구현. (50 R.P.M 에도 여유롭게 작동, 고 R.P.M 에도 OK )

●저렴한 원가,간단한 설계, 저소음,

저진동

●스핀코터의 정밀도(허용오차) 土1rpm 으로 매우 뛰어난 회전 정밀도

●회전수

표시,신뢰성이 높은 실회전수 표시 / LCD상 그래픽으로 스핀 구동을 실시간

볼 수가 있어 코팅 데이터를 쉽고 빠르게 구현하여

연구, 개발 시간이 대폭 줄어듭니다.

●스핀코터

프로그램은 최대 100스텝, 100프로그램 입력 가능

●스핀코터의 회전 속도 가속, 감속

(acceleration & deceleration) 자유롭게 구성 (최대 초당 3,000 R.P.M 가속, 가감)

●급 정지 가능 (여러가지 시료 및 포토레지스트, 화학약품에 대응

●위치 제어 기능으로 정지시 원하는 위치에 정지 (시료 Handling에도 최적)

●저속, 고속 R.P.M 에도 안정적으로 코팅 구현

![]() 스핀코터(SPIN

COATER)

관련 동아무역

News 클릭~!!

스핀코터(SPIN

COATER)

관련 동아무역

News 클릭~!!

상기 스핀코터의 간단한 사양과 외형은 당사에 의해서 변형이 될 수 있습니다.

![]() 카드 결제 가능.

카드 결제 가능.

당사가 공급하는 스핀코터 및 타사 제품도 당사의 노하우로 수리하여 공급하오니 많은 문의 바랍니다. 또한 기존의 스핀코터도 보상 처리하여 판매합니다.

TEL : 02- 868 - 8787 (代) pcb@naver.com

Spincoater system Profiling (acceleration & deceleration free)

Reference Data to purchase for spin coater as follow :

1. SPIN COATER (MODEL: TOP-8) : Using to vacuum chuck 5 to 8 inch is very good.

2. SPIN COATER (MODEL: ACE-200) : Using to vacuum chuck 4 inch under is very good.

Optional Vacuum chucks

Spin Coater Chuck Selection (스핀코터 버큠 척 종류)

Chucks are machined to close tolerances and provide an exceptionally flat, rigid surface for mounting substrates of different sizes, weights, and shapes. Custom chucks are also available.

Proper chuck

selection should be based upon substrate size and rigidity. The proper chuck

diameter is 1/4 to 1 inch smaller than the substrate diameter.

The entire

substrate should be supported if it is flexible, fragile, or when it is to be

wiped or brushed during cleaning.

Vacuum chucks are available in stainless

steel, hard anodized aluminum. Please specify the material of choice and chuck

size when ordering

스핀코터

Type CS chuck

스핀코터

Type CS chuck

실리콘, 글라스, 게르마늄 웨이퍼

스핀코터

Type H chuck

스핀코터

Type H chuck

글래스, 쿼츠, 세라믹, 메탈 플래이트

스핀코터

Type L chuck

스핀코터

Type L chuck

두꺼운 비대칭 기판

스핀코터

Type R chuck

스핀코터

Type R chuck

정방형 플래이트, 사용자 주문 사양

![]() 카드 결제 가능

카드 결제 가능

다이아몬드 커터기 (Diamond SAW)에 관심이 계시면 여기를 클릭해 주십시오.

폴리셔(polisher: 시편 연마기)에 관심이 계시면 여기를 클릭해 주십시오.

핫플레이트 Model 250 Digital

Controlled Alumnium Hot Plate for Mounting Samples ( 8.4" x5")

핫플레이트 Model 250 Digital

Controlled Alumnium Hot Plate for Mounting Samples ( 8.4" x5")

Digital Controlled Precision Heating

Plate

also useful to precision heating almost all kinds of chemicals and

liquid.

Features:

|

Model

250

(1220)

Power supply

AC 110V, 50-60

Hz

Power

600VA

Max.

temperature

200

0C

Accuracy

+/- 1.0

0C

Heating area

214 x 125 mm ( 8.4" x

5")

Dimension

240 x 240 x 160

mm

Net weight:

11.0 lbs (5

kg)

핫프레이트 Model 3040 Digital

Controlled Precision Hot Plate for Mounting Sample (15"x11")

핫프레이트 Model 3040 Digital

Controlled Precision Hot Plate for Mounting Sample (15"x11")

|

Digital Controlled Precision Heating

Plate precision

heating plate is designed for wax sample mounting in crystal substrates during

polishing. It is also useful to precision heating almost all kinds of chemicals

and liquid.

|

|

Features:

Specifications: |

| Model | 3040 |

| Power supply | AC 110V, 50-60 Hz |

| Power | 1200 VA |

| Max. temperature | 280 0C (5360F) |

| Accuracy | +/- 1 0C |

| Heating area | 373 x 273 mm (14.7" x 10.7") |

| Dimension | 337 x 400 x 135 mm (13.3" x 15.7" x 5.3") |

| Net weight: | ~30 lbs (~14 kg) |

![]() English

site

English

site

![]() Japan site

Japan site

![]() China Site

China Site

Dispencer : 스핀코터용 디스펜서 (Option )

DATC-101

| ||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||

스핀코터(ACE-200)의 동영상을 보시려면 여기를 클릭 하시면 자세히 보실수 있습니다.

Hot Plate

Model:

HP-411

Model:

HP-411

사 양

※ 퍼스널 컴퓨터와의 접속에는 별도 통신 변환기와 통신 소프트가 필요합니다.

장 점

![]() 스핀코터

관련 동아무역

News

스핀코터

관련 동아무역

News

![]() 스핀코터 사양 첨부파일

클릭하시면 자세하게 보실수 있습니다.

스핀코터 사양 첨부파일

클릭하시면 자세하게 보실수 있습니다.

당사가 공급하는 스핀코터 물론 타사 제품도 수리 또는 보상 판매하여 공급하오니 많은 문의 바랍니다.

TEL : 02 - 868 - 8787 (代) FAX : 02- 868 - 0664